Article: What are 3D printed ceramics and how can they elevate your space?

What are 3D printed ceramics and how can they elevate your space?

Before we answer the question about what exactly 3D printed ceramics are, let us start with a brief overview of what 3D printing entails.

While 3D printing is a term that you may see everywhere today, it is a relatively new, fascinating yet evolving technology that keeps surprising us with its ability to adapt to different materials. The concept of 3D printing involves building objects layer by layer with the help of a digital 3D model.

Although the earliest idea of 3D printing has been around since 1945, it wasn’t until the 1970s that it was put into practice, driven by efforts to make manufacturing faster and more efficient. The first material used in 3D printing was a resin that could be polymerised by UV light. Since then, 3D printing has evolved to print with materials like plastic, metals, and even clay.

3D Printing Ceramics: What are they and How are They Made?

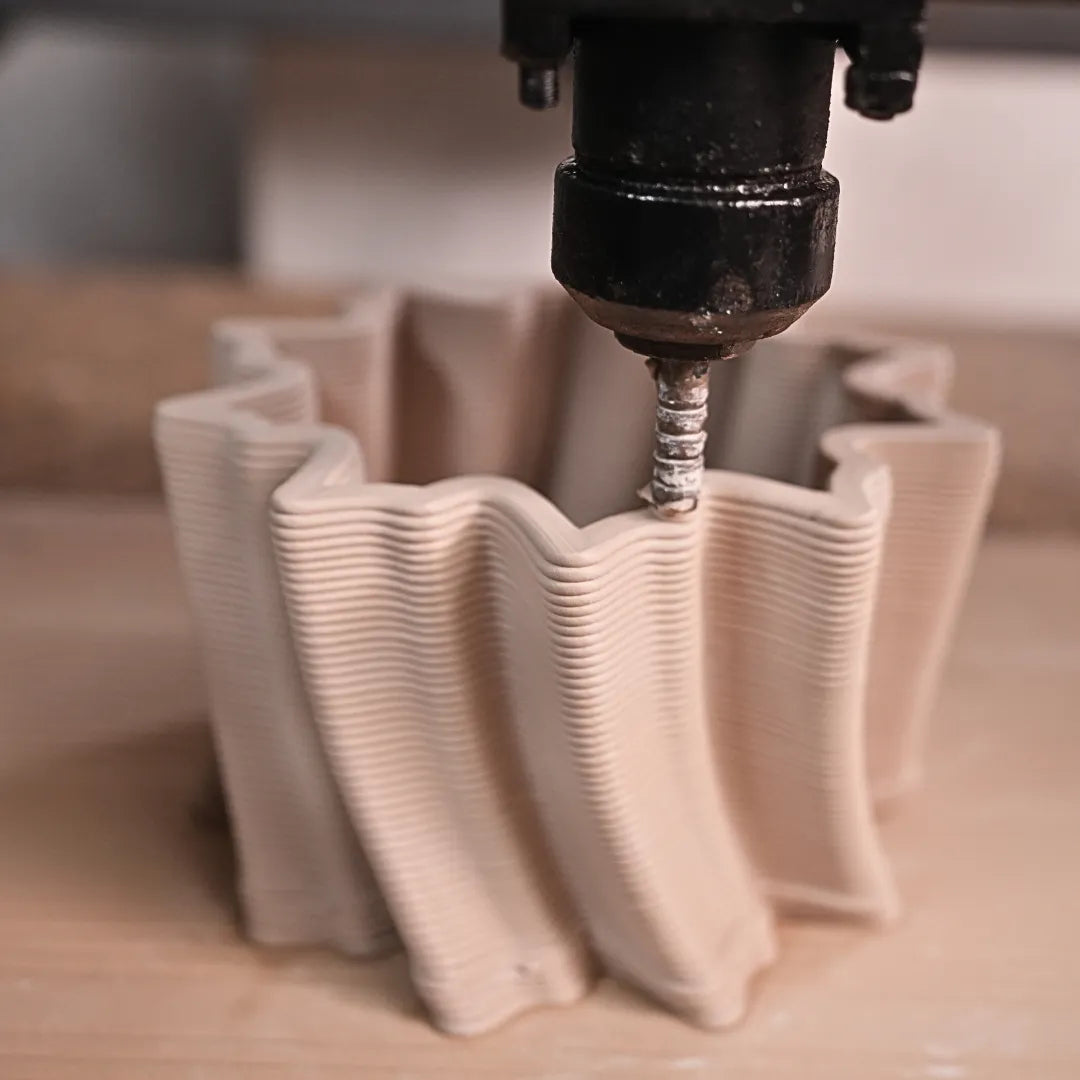

3D printing ceramics is the meeting point of the age-old craft of pottery and modern technology that allows us to create intricate and unique pieces of ceramics.

The process utilises clay or ceramic powders mixed with water to create a mixture that can be extruded and easily layered. This innovation brings forth the opportunity for design freedom, enabling artists to create complex shapes that would otherwise be impossible to achieve by hand.

3D printing clay not only preserves the heritage of pottery but also adds layers (pun intended) of contemporary design to the craft. Other than pottery, 3D printing clay is being embraced across various industries, from arts to architecture, and is also used for manufacturing ceramic components for complex machinery.

Why 3D Printing Clay is Different from Traditional Pottery?

The most apparent difference that 3D printing clay involves is, of course, the technology. However, if we dive a little deeper, there are other factors that appear. Traditional pottery involves hand shaping using a wheel or hand-building techniques, where the artisan moulds the piece and manipulates the clay into a desired shape.

In contrast, 3D printing ceramics incorporates an additional step of digitally designing the piece before it is sent to printing. This significantly nudges the threshold and potential for customization. Unlike, handmade ceramics where complex shapes would often require a mould or have to be meticulously built by hand, one by one, 3D printing clay allows for each piece to be designed and tailored to specific dimensions without the need for moulds. This gives us the flexibility to create extremely complex geometric and intricate patterns.

Other than that, the materials, though fundamentally the same, are prepared in different ways. Traditional pottery requires the clay to be processed through kneading and adding water to achieve the right consistency that allows for it to be easily manipulated by hand. Whereas, 3D printing clay requires the clay to be formulated in such a way that it can easily flow out of the printer, yet is strong enough to retain the shape without warping or falling apart.

The cherry on top of the cake, the added bonus of 3D printing ceramics lies in its efficiency and environmental impact. 3D printing eliminates the need for mould making, which is a highly energy intensive process, thereby, saving energy and reducing the carbon footprint of the production process. Lastly, the layer by layer printing approach minimises waste of material by only using the necessary amount for the piece. Clay, itself is a great sustainable material that offers a chance for reusability and recycling in case of faulty printing. This makes the entire process very eco friendly and sustainable.

What Makes 3D Printed Ceramics a Premium Choice?

We have already discussed how 3D printed ceramics blend an age-old art form with cutting-edge technology to create magnificently unique pieces of ceramics that would otherwise be challenging or even impossible to make by hand. But that is not the only reason why it can be considered a high-end product. To truly appreciate the products, we would like to take you through the meticulous process of creating these pieces and challenges to explain why.

The Process

3D Printing clay involves a series of steps that require both care and precision. Here is a brief overview of how we achieve these products for you.

The journey of 3D printing ceramics begins with conceptualising the design while carefully considering both aesthetics and function. This stage involves a lot of thought behind factors like the stability, structural integrity of the material and the overall function of the product. Once the design process is complete, we move on to creating a digital model of the piece using CAD software. (Computer Aided Design software).

The next step in the process involves preparing the material that is to be printed, in our case, clay. Ensuring the smooth and flowy consistency of clay is crucial for the printing process. But the journey does not end with printing. Once the piece is printed, it is dried to remove excess moisture and then fired in a kiln to strengthen the piece and make it durable. Firing is the part of the process that transforms clay into ceramic. And then follows the final step, the finishing of the product – be it paint, glazing or polishing.

Challenges

As we have mentioned before, preparing the clay to achieve the right consistency is crucial to the 3D printing process. However, it is equally important to ensure that the clay maintains its structural integrity throughout the printing cycle to avoid warping or uneven breaks in the piece.

Firing is the pivotal make or break stage for the products. It is the stage that transforms clay into ceramic and solidifies the final piece. However, during this stage, temperature and duration play a key role in the final outcome of the product. An improper firing can lead to warping, cracking or disfiguration of the piece. Therefore, it is important to constantly and meticulously monitor and control the firing conditions of the kiln to ensure that the piece emerges from it in the best and intended form.

Lastly, the finishing of the product can become a little complicated due to the intricacies and geometric patterns of the pieces. To achieve a uniform and aesthetically pleasing finish, the piece often undergoes extensive post production including sanding, glazing, and polishing. These steps can add time and labour to the overall production process but are necessary to craft high end quality that is expected from 3D printed ceramics.

The Verdict

Now you know, the meticulous design process to craft something unique, the precision and materiality knowledge required in preparing the perfect viscosity of the clay, the technology used for printing these pieces, and the extensive post production process – all add to the sophistication and quality of the products, elevating its status to a premium work of art.

How Can 3D Printed Ceramic Decor Elevate Interiors of a Space?

Ceramic home décor has always held a timeless appeal in the world of interior designing – offering functional value while bringing colour and texture to the space it is added to. The introduction of 3D printed ceramics is once again revolutionising the role of ceramics in interiors, only this time, the ceramics are more of a standalone work of art, a sculpture by itself regardless of the function they serve. These pieces don't just fill space—they bring a sculptural elegance that enhances any setting, making them a thoughtful choice for those seeking to elevate their interiors with innovative and sustainable design.

For instance, Ceramic vases made by 3D printing clay stand out with their intricate, geometric patterns and details that are rarely seen in traditional handmade ceramics. These unique pieces can serve as a standalone sculptural element, adding an artistic focal point to the room, and elevating the room’s visual into a more elegant picture.

3D printing ceramics encompasses a wide range of décor items, ranging from ceramic sculptures to functional items like ceramic trays and plates. Their versatility makes it ideal for them to fit into any style of interior space and effortlessly complement it, be it minimalistic, contemporary or a bold maximalist space. Each piece adds depth and character to the room while harmonising with the décor.

Where Can I Find 3D Printed Ceramics in India?

You must be wondering where to find these exquisite 3D printed ceramics in India. CeraPrint masterfully merges artistry with state of the art technology to bring forth stunning bespoke ceramic décor for your home. Our speciality lies in crafting accent pieces - including ceramic vases, ceramic sculptures, ceramic trays, planters and, wall murals, all designed to elevate your interiors with a one of a kind charm. Each piece of ceramic decor reflects our dedication to craftsmanship and enhancing the space it inhabits. The main goal of our creations is to make a striking statement in any setting. Explore our catalogue of products to discover the perfect decor for any space.